Totem-Pole PFC: HP1010 power your Two-wheeler journey green, fast, safe

3 25, 2024

Two-wheeler ensures convenient, healthy, and green lifestyle in today’s life. Imaging you fully rested, recharged overnight ready to start a new day, would you want to curtail the fun with worrying of how to charge your beloved bike?

Charing stations of two-wheelers prevail as more and more people choose to bike through the day for healthy, green convenience. So are the accident associated with these charging stations, reported across various media. Of course, there are many factors to consider when designing charging facilities, e.g. capacity, communication protocols, system efficiency, safety and so on. This article only focuses on how Totem-Pole PFC of HP1010 contributes to safe, flexible, and smart power supply for the two-wheeler applications.

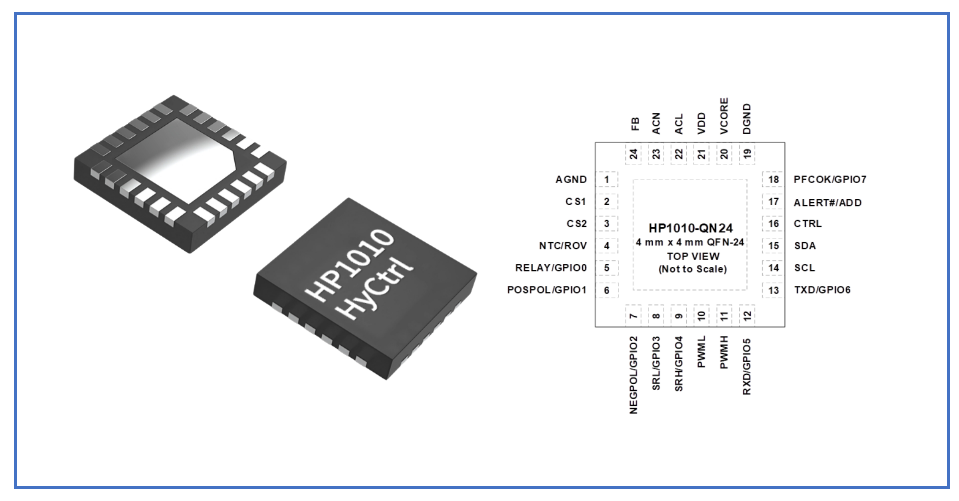

The HP1010 is available in a QFN-24L package, just 4 mm x 4 mm. The chip has intelligent switching modes (CCM, DCM, and Burst Mode) adapting to different load conditions, especially for better light-load efficiency. A very comprehensive set of programmable protections, including: cycle-by-cycle current limit protection, surge protection, input and output voltage over/under voltage protection, output feedback voltage open-circuit protection, etc., the protection function parameters and enable can be independently configured. Chip functions can be configured to meet the needs of new solutions using only graphical user interface (GUI) software, accelerating product design and time-to-market.

Figure 1: HP1010 package

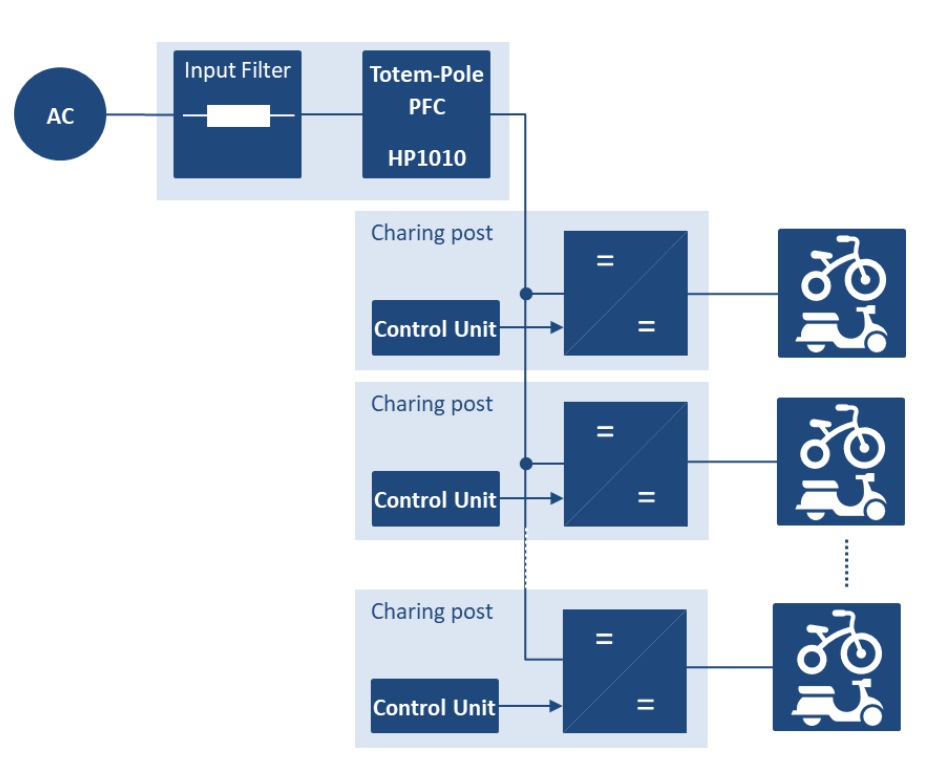

Figure 2: Totem-pole PFC HP1010 in two-wheeler charging system

GREEN &POWER SAVING

One of the outstanding advantages of the Totem-Pole PFC topology is its high efficiency. In traditional PFC circuit with rectifier bridge, losses of rectifier devices are unavoidable. This loss is especially noticeable at low input voltage. At the same time, with the increase of power, the heat dissipation problem of the bridge stack also threatens reliability and stability of the system operations. As in Figure 2, taking a 3 kW electric two-wheeler charging station as an example, the system adopts a totem-pole PFC and LLC topology architecture to realize the conversion from AC input voltage to DC output voltage. The power scalability can be realised by the number of paralleled LLCs, ranging from a single LLC path with kilowatt output to several hundred watts on each path in shunt. In such way, when at a low input voltage, around 1% power could be saved. This is exactly why HP1010 is used in such application to greatly reduce the loss. According to industry experts of the battery swapping cabinet, the average daily electricity cost of each station is 55 RMB. Adopting the HP1010 solution, the system efficiency is improved, which not only reduced the electricity cost of the charging station, improved the operating profit, but also greatly minimised the risk of hazards caused by "heat".

In addition, it is worth to mention the "green value" grounded by higher efficiency. According to the "2022 Two-Wheeled Green Travel Index Research Report", the daily carbon emission reduction thanks to two-wheeled travel is equivalent to planting 550,000 trees. Additionally, HP1010 enabled even higher efficient charging system, which can further reduce CO2 emissions and make your journey more environmentally friendly.

MEETING STANDARS:POWER MONITORING & EMI

Leanings after the unfortunate accidents yield much savvier solutions to charge two-wheelers. Particularly, to meet the stringent requirements of GB 42296 – 2022, GB 42295-2022, UL 2849 and EN 15194, engineers are pouring much effort into safety, scalability, and intelligence. This article will explain how Totem-Pole PFC HP1010 addresses this most recent learnings.

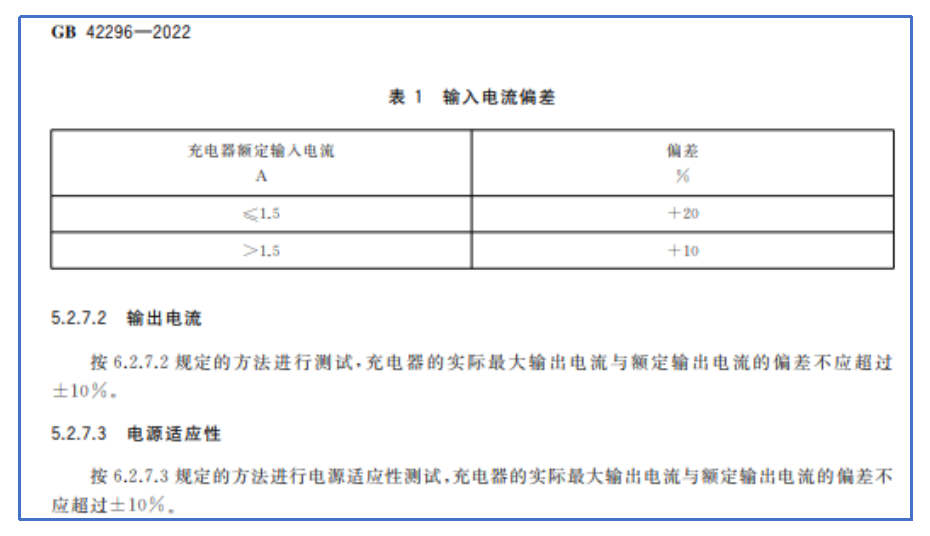

How much current goes in and out of the charging system is an essential piece of information, especially for battery load, for which safety is on top of all other factors. Figure 3 illustrates an extract from compulsory standard, activated on July 1, 2023. It clearly states that both input and output current of two-wheeler chargers must remain as close as possible to its intended value. To aid designers, thanks to its advanced analogue front-end and digital core, HP1010 enables power monitoring by offering input RMS current, input RMS voltage, thus input RMS power, and PFC output current and voltage. In fact, there are eight parameters can be tailored according to the design specifics. Not only for current information, voltage, power range and update cycles are additionally available as well, moreover, all of which can be read through I2C and UART interface. Detailed information please refer to HP1010 GUI USER GUIDE (hynetek.com)

Figure 3: extract from GB 42296 -2022 on input/output current monitoring

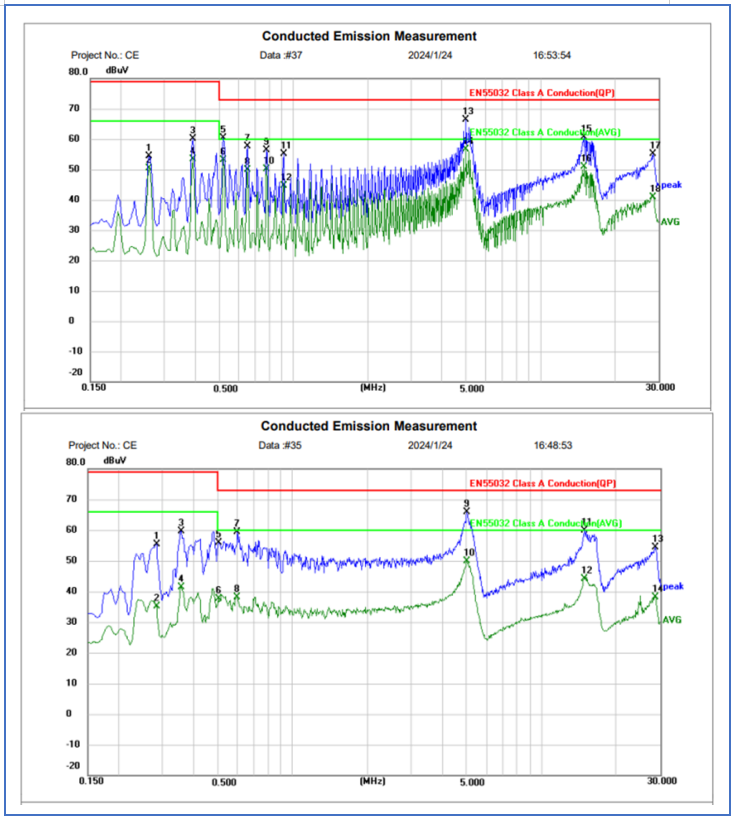

On the other hand, EMI compliance is also newly added into this update, referring to section 5.7 of the official release of GB 42296-2022. Again, HP1010 has advanced feature of frequency dithering to tackle this issue. As shown in figure 4, EMI performance has been improved across wide frequency spectrum once this function enabled. HP1010 alters the switching frequency through a configurable number of cycles given in the relevant register. There are eight value steps available to satisfy the design requirement.

Figure 4: EMI comparison with and without frequency dithering

AGAINST HEAT,HUMIDITY AND LIGHTNING

Charging facilities are normally outdoor, exposed to harsh weather conditions, heat, humidity, or lightning. HP1010 offers a rather comprehensive set of protections to prevent these problems. Here are three of the highlights.

First, avoid the fire. Over-Temperature Protection (OTP) will be triggered once the voltage of the NTC pin is pulled lower than 0.4V. Engineers can customise OTP debounce time and response according to their design need.

Second, prohibit unwanted conduction from humidity. Short circuit protection through CS1/CS2 pins. The PFC IC of HP1010 will not start until it is certain that there is no short connection on these two pins. The dimensioning circuit is rather concise by simply comparing the pin voltage with reference of 150 mV. For more detailed circuit, please refer to the datasheet (hynetek.com).

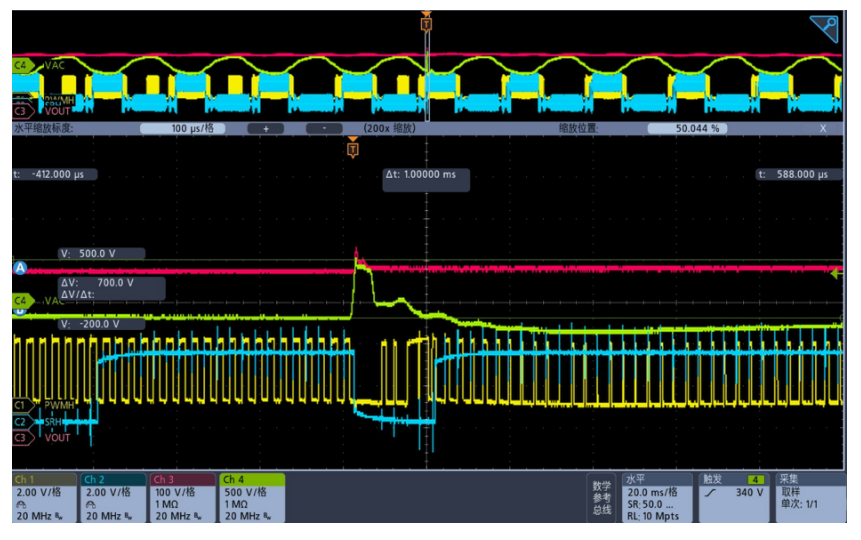

Third, defend against lightning. Measurement in figure 5 has demonstrated that HP1010 has excellent performance against lightnings. Lightnings could occur either in-phase or out-phase of AC voltage. The advanced control algorithm of HP1010 ensures that even at the much more challenged situation, out-phase case, the PFC could very quickly switch off the slow-leg FETs and recover smartly and safely. In comparison with conventional bridge PFC IC, this is extraordinary achievement. Because Totem-Pole PFC is constructed without rectifier bridge. Hence loss is removed. But this also means that any disturbance from AC side will be exerted directly on power FETs, including lightning strikes. Exactly for its robustness, HP1010 is widely adopted by engineers.

Figure 5: negative AC cycle with positive strike

To sum up, in the trend of promoting energy conservation and green travel, electric two-wheelers are becoming increasingly popular worldwide. National standards and industrial technologies continue to propel the progress in terms of both better efficiency and safety. This aligns perfectly with the mission of Hynetek Semiconductor: "IC Intelligent, IC Energetic, jointly building a green future." The newly launched digital PFC controller, HP1010, not only maximized the efficiency of the Totem-Pole topology but also turned the long-awaited engineering dream of flexible & safe design into reality.