HP1010A Advanced Edition Totem Pole PFC Arrives, Packing Powerful Features and Superior Performance

12 9, 2025

From data center servers operating around the clock to industrial power supplies requiring adaptation to various extreme environments, the demand for efficient and highly reliable power solutions continues to grow. With the widespread adoption of third-generation semiconductor devices like gallium nitride (GaN) and silicon carbide (SiC), the application scope of Totem Pole Bridge-less PFC (TPPFC) has expanded significantly. Compared to traditional bridge-based PFC topologies, Totem Pole Bridge-less PFC offers numerous advantages: lower switching losses, higher efficiency, and a highly competitive compact footprint. It meets stringent efficiency standards and is ideal for ultra-compact power supply applications. However, without the isolation and protection provided by a bridge rectifier, the input AC voltage is directly applied to the switching transistor in the totem-pole topology. This leaves the power system highly vulnerable to damage from faults such as overcurrent, surge overvoltage, and input voltage dips. Meeting safety and various protection requirements becomes challenging, leaving power engineers both drawn to and wary of the totem-pole bridge-less PFC topology.

To address various challenges encountered in Totem PFC applications, Hynetek launched the industry's first dedicated Totem PFC digital controller, the HP1010, in 2023. After nearly two years of client-side deployment, the HP1010 has thoroughly demonstrated its stability and reliability. Today, Huinengtai introduces the iterative upgrade to the HP1010: the HP1010A. Compared to the HP1010, the HP1010A offers enhanced ease of use and provides pin-to-pin compatibility for seamless replacement. Additionally, the HP1010A incorporates upgrades addressing new functional requirements raised by customers.

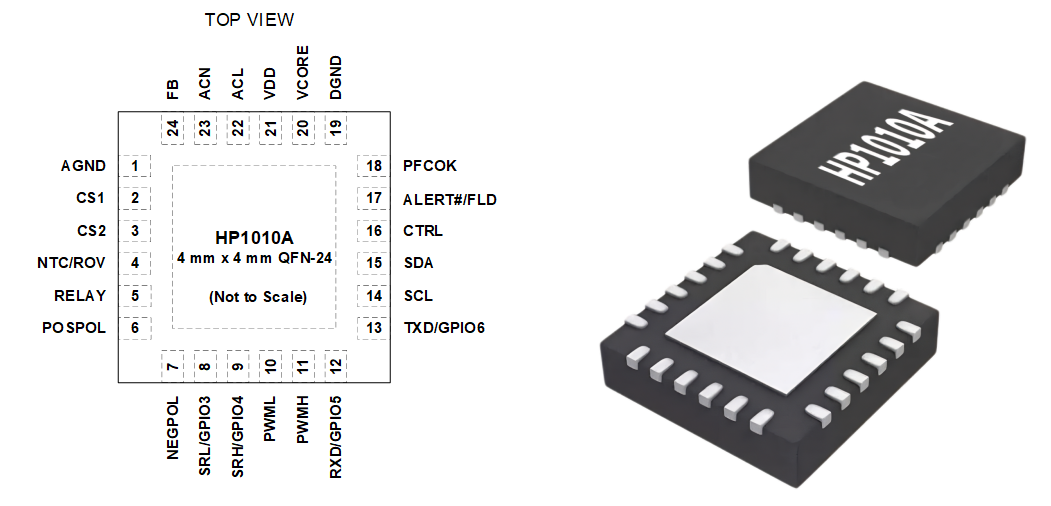

Figure 1: HP1010A Pinout and Package Diagram

FEATURES

Highly flexible digital Totem Pole PFC controller

High flexibility digital PWM

– PWM frequency ranges from 20 kHz to 200 kHz

– PWM soft start during AC line zero-crossing

– Switching frequency spread spectrum for improved EMI

High performance control loop

– 25 MHz sigma-delta ADC for line voltage and current sense, 12.5 MHz sigma-delta ADC for output voltage

– Enhanced dynamic loop response

– Input voltage feedforward to avoid reverse current during AC drop

– Control loop parameters can be configured separately for operating modes and input voltage

– Support HVDC input

Multi−mode operations

– Continuous Conduction Mode (CCM) in heavy load Conditions

– Discontinuous Conduction Mode (DCM) in light load conditions

– Burst mode in the zero load conditions

– The mode parameters can be configured separately for high line and low line

Advanced control functions

– True RMS power metering

– Inrush current control with programming relay delay

– Output voltage follows power variation

– Relay power-saving mode

– PFC quick start function

Extensive fault protections

– Fast over-voltage protection

– Bulk under-voltage protection and over-voltage protection

– External NTC thermal protection

– Cycle−by−cycle current limit

– Average switching current protection

I 2C and UART interfaces

Programming via easy-to-use Graphical User Interface (GUI)

Available in QFN4×4-24L packages

-40°C to 125°C operating temperature

Typical Applications of the HP1010A

The HP1010A features a 4 mm x 4 mm QFN-24L package, integrating a high-speed ADC, comparator, and other high-performance analog front-end components. Its simplified peripheral circuitry enables a compact overall solution that occupies minimal PCB area, saving board space and effectively reducing BOM costs.

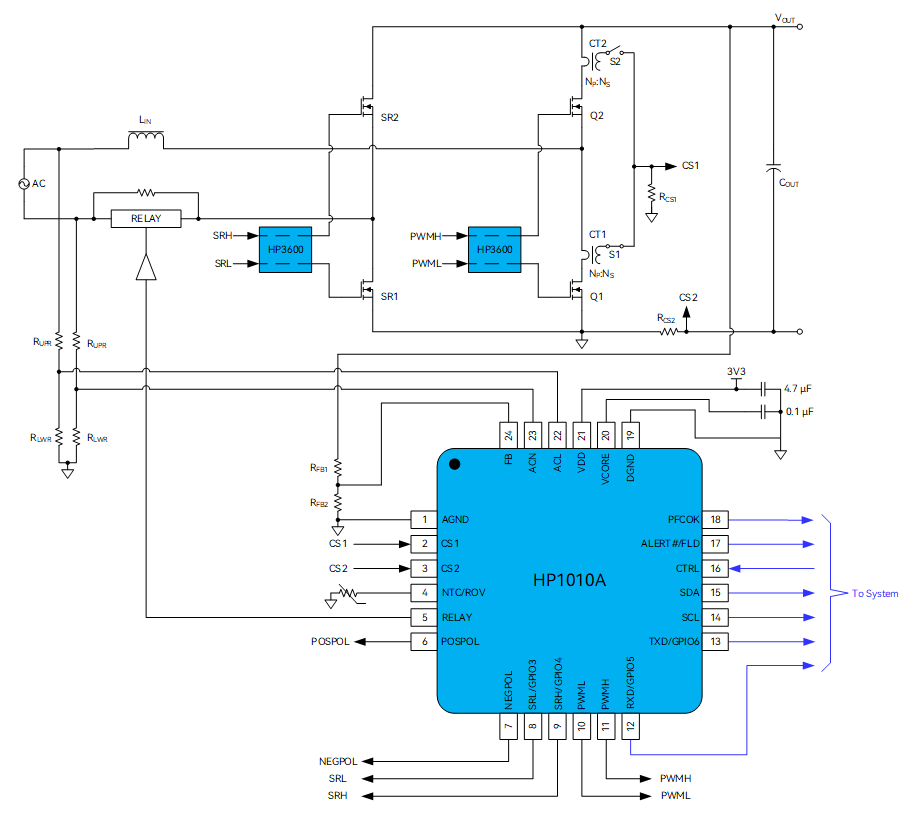

Figure 2: Typical Application Circuit Diagram for HP1010A

Advantages of the HP1010A System Solution

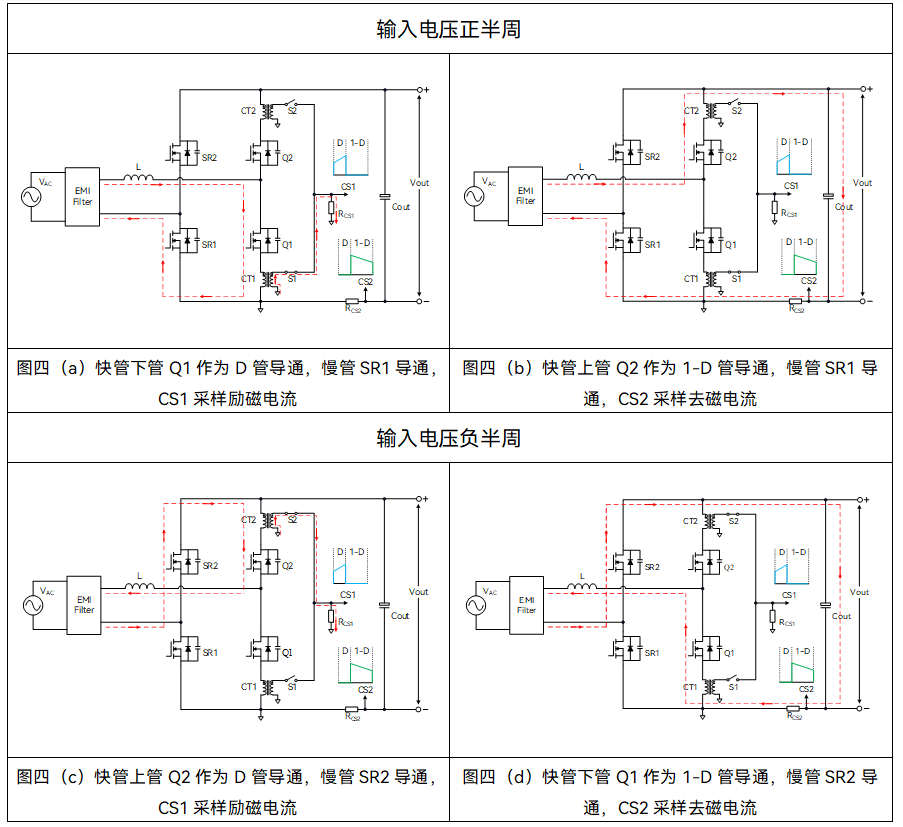

How the HP1010A System Solution Works

Efficiency Metrics

The HP1010A-based 1kW totem pole bridge-less PFC reference design achieves high-voltage full-load efficiency approaching 99% and low-voltage full-load efficiency exceeding 97.6%.

Figure 5: Efficiency Curve of 1kW Totem Pole PFC Evaluation Board

PF Value & THD Indicator

The HP1010A-based 1kW totem pole bridge-less PFC reference design achieves excellent PF and THD performance, with full-load THD remaining around 2% under both high and low voltage conditions.

Figure 6: PF Value & THD Metrics for 1kW Totem Pole PFC Evaluation Board

Load Dynamics

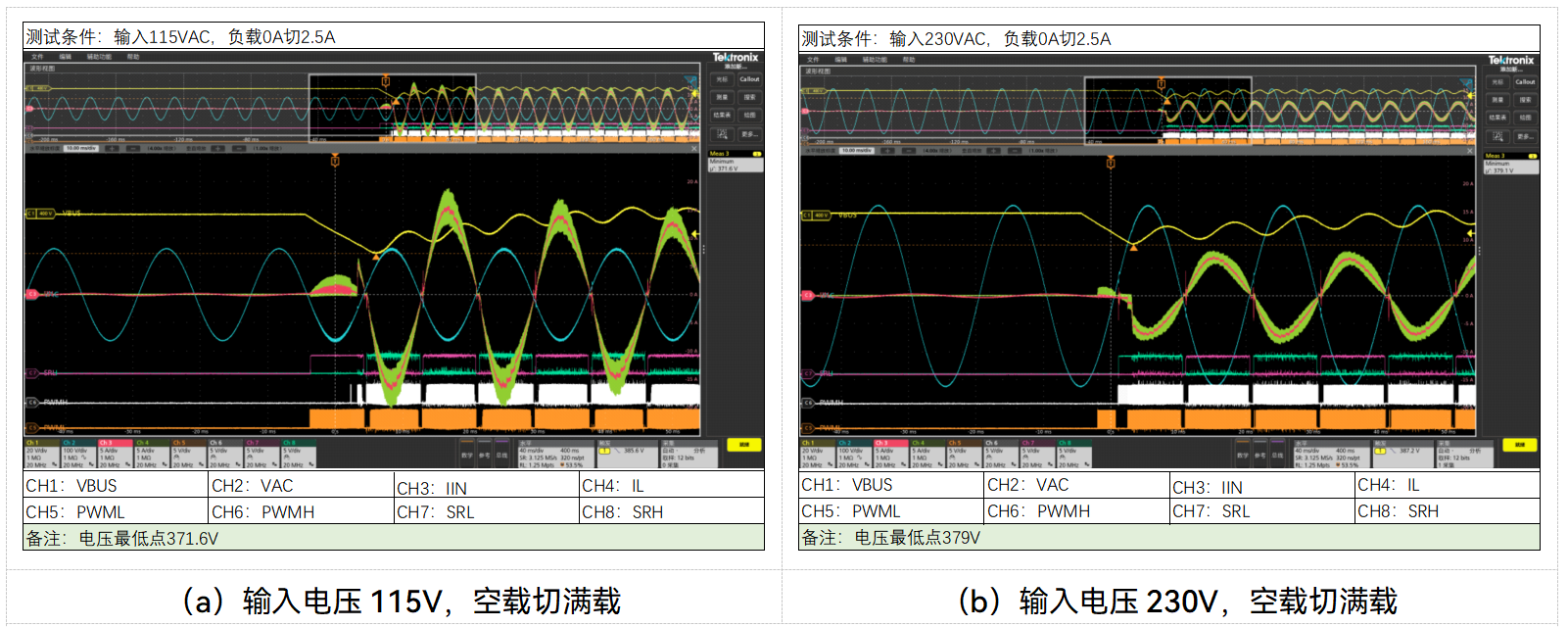

Based on testing with the 1kW Totem Pole PFC evaluation board, when the load transitions from no load to full load, the output voltage drop is less than 30V.

Figure 7: Dynamic Performance Metrics of the 1kW Totem Pole PFC Evaluation Board

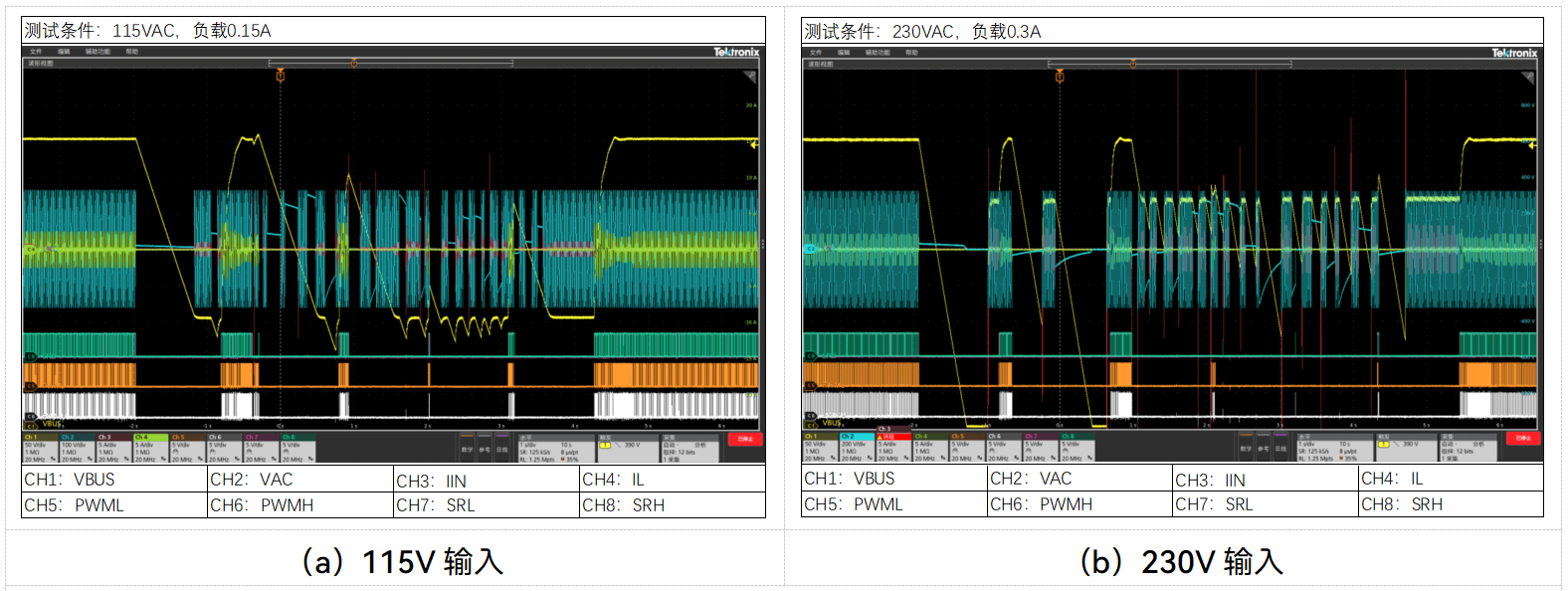

Input Dynamics

Input high-low voltage switching, system operates stably.

Figure 8: High-to-Low Voltage Switching at Full Load on the 1kW Totem Pole PFC Evaluation Board

Input Voltage Drop Test

The system operates normally under various phase and dropout duration tests, with no drive polarity errors.

Figure 9: Drop Test of 1kW Totem Pole PFC Evaluation Board Under Full Load Conditions

Input Hot-Swap Testing

During hot-swap testing, the driver exhibited no polarity errors and operated with normal logic.

Figure 10: Hot-Swap Testing of 1kW Totem Pole PFC Evaluation Board

Surge Test

The system also functions normally when tested under a 6kV surge.

Figure 11: 6kV Surge Test of 1kW Totem Pole PFC Evaluation Board

HP1010A New Features

The PFC output voltage's ability to track power changes, when paired with the downstream DC-DC converter, enables customers to achieve optimal system efficiency.

Figure 12: PFC Output Voltage Tracking Power Changes Function

Under light load conditions, the Relay's power-saving mode can disable the Relay driver, reducing its power consumption. This is particularly suitable for applications with stringent standby power requirements.

Figure 13: Relay Power-Saving Mode

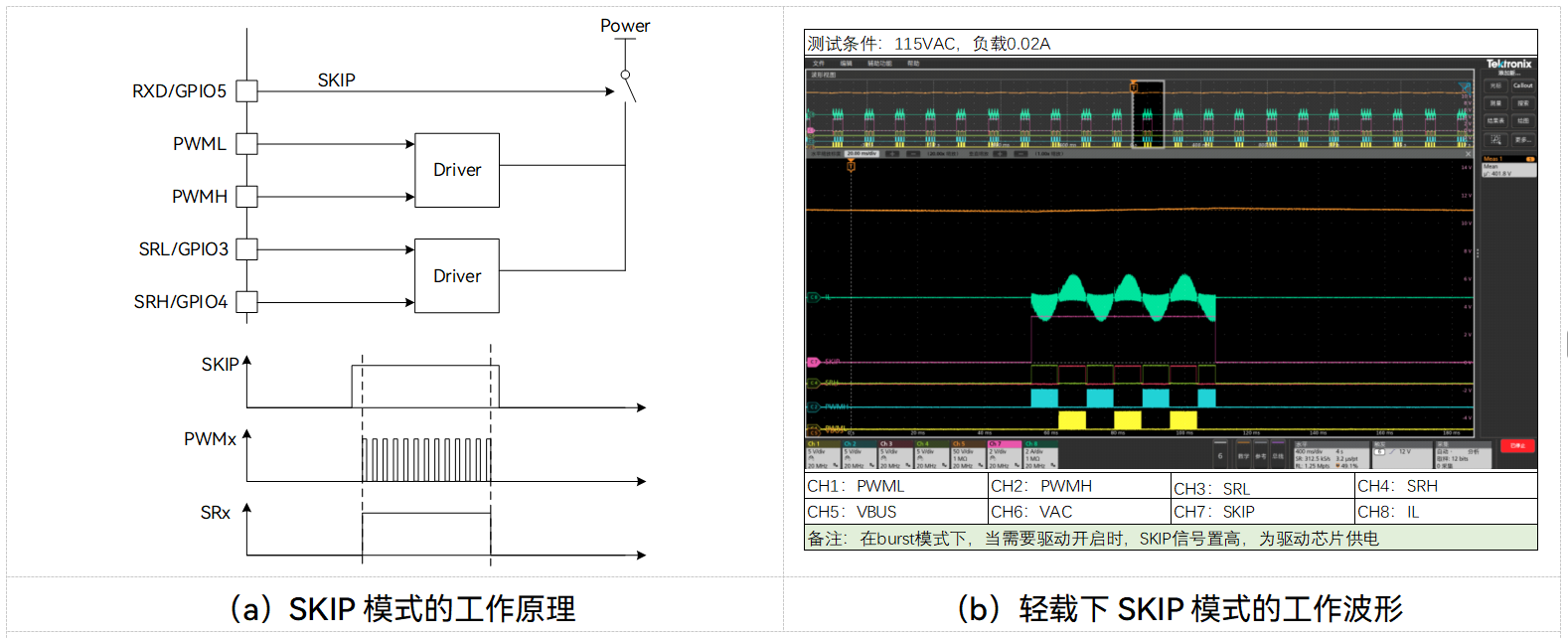

The SKIP function further optimizes no-load standby power consumption. By multiplexing GPIO5 with the SKIP function, the PFC can disable power supply to the driver chip when not required during burst mode operation, thereby reducing driver losses.

Figure 14: SKIP Mode

The soft-start function of PWM during load changes can reduce interference to the system.

Figure 15: Soft Start Function of PWM

The Precharge function can charge the bootstrap capacitor of the driver chip.

Figure 16: Precharge Function

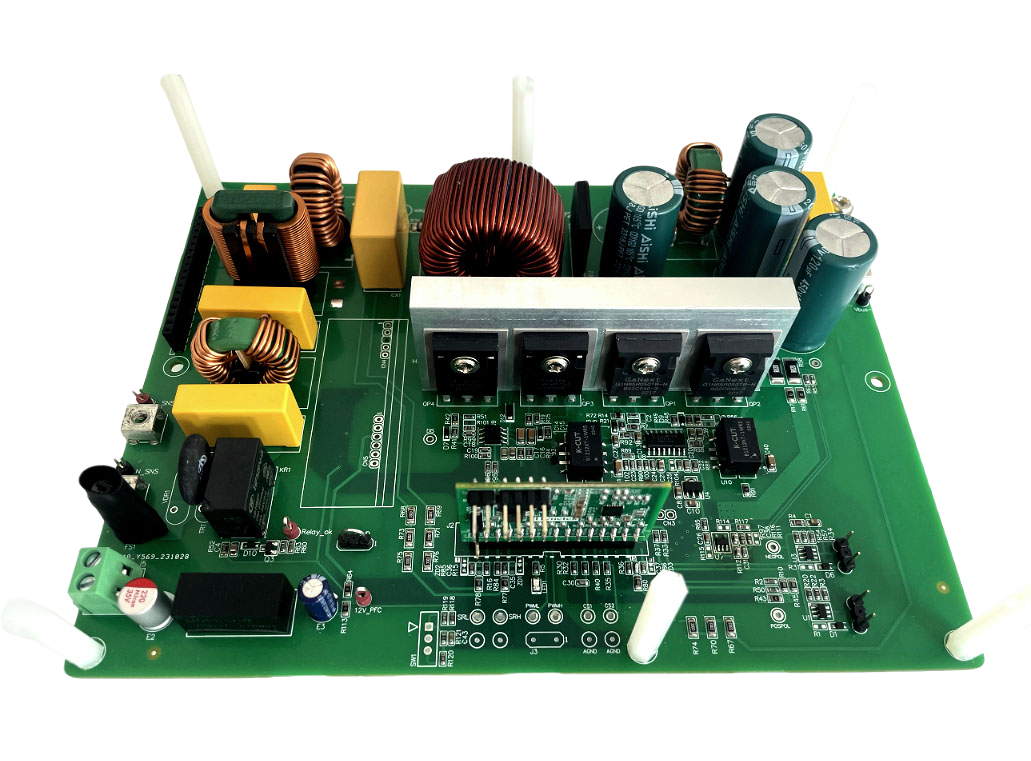

HP1010A 1000W Evaluation Board

Hynetek has simultaneously launched the HP1010A 1kW evaluation board. Its key specifications are as follows:

Input voltage range: 90 VAC ~ 264 VAC

Output voltage: 400 VDC

Output power: 1kW

Typical efficiency: 98.7%

Figure 17: 1kW Evaluation Board Using HP1010A